i-moulding: moldeo por inyección,injection molding

The application is to calculate the initial parameters to be placed in the injection molding machine, injection molding, injection molding, injection of polymers such as:

- pad mass (cm3) or (mm).

- closing force required to close the mold (kN).

- Cooling time depending on the thickness of the piece and the material (s).

- Volume injected (cm3) or stroke (mm).

- maximum dosing rate (rpm mm / s) and maximum pressure (bar)

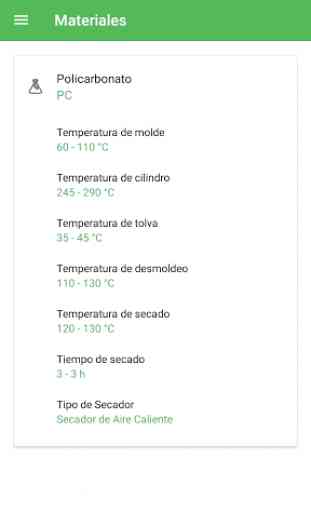

- according to the material temperatures (barrel zone, hopper and expulsion of the pieces).

- Drying conditions for materials that require drying.

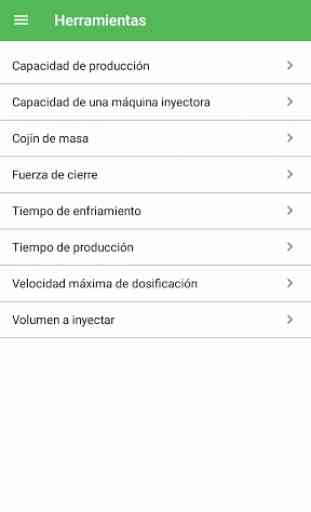

You can also calculate some values are always used in the plastics industry as:

- Production capacity (depending on the cycle time, number of cavities and production efficiency).

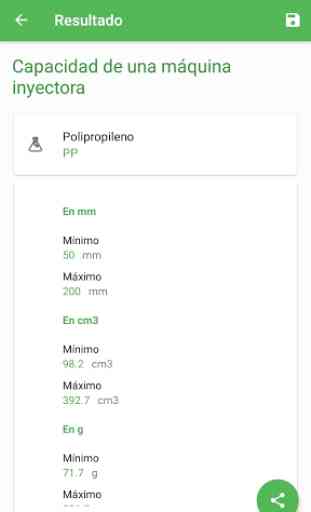

- Ability of an injection machine (mm Volume cm3 or recommended by injecting the material to be injected, diameter and L / D ratio of the screw).

- Injection time (the time it takes to produce a required amount according to the number of cavities enabled and efficiency of the machine).

You can also:

- Save calculations (full version).

- Send the calculations you who want (full version)..

- Access to a basic course injection molding (full version soon).

- Defect conditions Injection access. (Full version soon).

Any questions or suggestions please write to [email protected]

Atte

Peruvian Center of Plastic

- pad mass (cm3) or (mm).

- closing force required to close the mold (kN).

- Cooling time depending on the thickness of the piece and the material (s).

- Volume injected (cm3) or stroke (mm).

- maximum dosing rate (rpm mm / s) and maximum pressure (bar)

- according to the material temperatures (barrel zone, hopper and expulsion of the pieces).

- Drying conditions for materials that require drying.

You can also calculate some values are always used in the plastics industry as:

- Production capacity (depending on the cycle time, number of cavities and production efficiency).

- Ability of an injection machine (mm Volume cm3 or recommended by injecting the material to be injected, diameter and L / D ratio of the screw).

- Injection time (the time it takes to produce a required amount according to the number of cavities enabled and efficiency of the machine).

You can also:

- Save calculations (full version).

- Send the calculations you who want (full version)..

- Access to a basic course injection molding (full version soon).

- Defect conditions Injection access. (Full version soon).

Any questions or suggestions please write to [email protected]

Atte

Peruvian Center of Plastic

Category : Tools

Related searches