Lean Manufacturing Lite

★ Deploy Lean Manufacturing to significantly improve the operational efficiency of your Production System: reducing wastes and maximizing profits. This approach is particularly effective in this current period of economic crisis. This will give you a strong competitive advantage.

★ This application allows you to:

- deploy Lean Manufacturing (Paid version only): tool by tool, area by area, by a business approach,

- continuously treat production data on workplace, in collaboration with operators.

★ Deploy Lean Manufacturing around these pillars (Paid version only):

- 5S,

- visual management,

- standardization of operations,

- production leveling.

★ The “Deploy” part (Paid version only) consists of practical explanations, illustrated by many drawings:

- Determine where you should start your continuous improvement approach

- Make work environment cleaner and safer

- Develop communication tools through a visual management

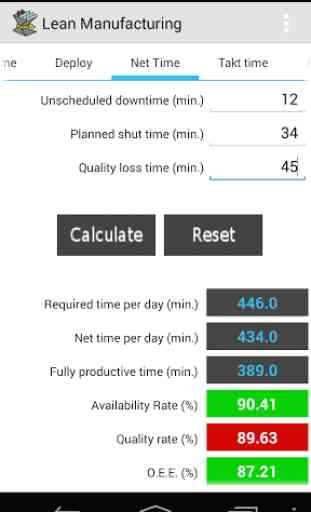

- Calculate time really available for manufacture

- Identify and eliminate wastes of Value Added

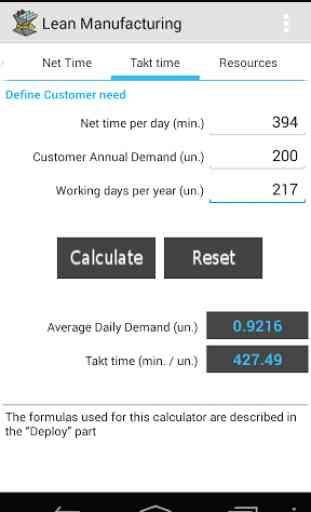

- Adjust production cycle on the need of customer through Takt time

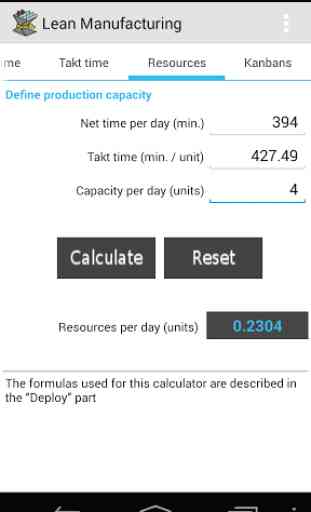

- Assign resources strictly necessary for manufacture

- Reduce your changeover time

- Build a Kanbans schedule to manage workflow by Just-In-Time

- Sustain Lean through a structured approach

★ Calculate easily major indicators of Lean: Required Time, Net Time, Fully Productive Time, Availability Rate, Quality rate, OEE Overall Equipment Effectiveness, Average Daily Demand, Takt time, Resources, Kanban.

★ Send data (collected and calculated) by email.

★ No particular knowledge is required to use this application:

- Lean beginners will appreciate: road map to self deploy Lean, topics that may be read independently, explanations with lot of drawings, calculators for main Lean indicators, send questions to authors;

- Lean experts will appreciate: materials to use on workplace, concrete examples.

★ Improve this app: if you want more information about a topic or if you want information about a new topic, contact us: [email protected].

★ Please, update this app to fully benefit of new topics, bug fixes or performance improvement. This app is updated regularly.

★ Keywords: 5M, 5S, Continuous improvement, Demand Flow Technology, Gemba, Heijunka, Hoshin kanri, Jidoka, Just-In-Time, Kaizen, Kanbans, Lean Manufacturing, Net time, OEE Overall Equipment Effectiveness, Muda, Mura, Muri, PDCA, Quality rate, Resources, Six Sigma, SMED, Standardization, Strategy deployment, Takt time, U-cell, Value added, VSM, Wastes, world class.

★ This application allows you to:

- deploy Lean Manufacturing (Paid version only): tool by tool, area by area, by a business approach,

- continuously treat production data on workplace, in collaboration with operators.

★ Deploy Lean Manufacturing around these pillars (Paid version only):

- 5S,

- visual management,

- standardization of operations,

- production leveling.

★ The “Deploy” part (Paid version only) consists of practical explanations, illustrated by many drawings:

- Determine where you should start your continuous improvement approach

- Make work environment cleaner and safer

- Develop communication tools through a visual management

- Calculate time really available for manufacture

- Identify and eliminate wastes of Value Added

- Adjust production cycle on the need of customer through Takt time

- Assign resources strictly necessary for manufacture

- Reduce your changeover time

- Build a Kanbans schedule to manage workflow by Just-In-Time

- Sustain Lean through a structured approach

★ Calculate easily major indicators of Lean: Required Time, Net Time, Fully Productive Time, Availability Rate, Quality rate, OEE Overall Equipment Effectiveness, Average Daily Demand, Takt time, Resources, Kanban.

★ Send data (collected and calculated) by email.

★ No particular knowledge is required to use this application:

- Lean beginners will appreciate: road map to self deploy Lean, topics that may be read independently, explanations with lot of drawings, calculators for main Lean indicators, send questions to authors;

- Lean experts will appreciate: materials to use on workplace, concrete examples.

★ Improve this app: if you want more information about a topic or if you want information about a new topic, contact us: [email protected].

★ Please, update this app to fully benefit of new topics, bug fixes or performance improvement. This app is updated regularly.

★ Keywords: 5M, 5S, Continuous improvement, Demand Flow Technology, Gemba, Heijunka, Hoshin kanri, Jidoka, Just-In-Time, Kaizen, Kanbans, Lean Manufacturing, Net time, OEE Overall Equipment Effectiveness, Muda, Mura, Muri, PDCA, Quality rate, Resources, Six Sigma, SMED, Standardization, Strategy deployment, Takt time, U-cell, Value added, VSM, Wastes, world class.

Established : 1999.

Corporate Office : Mumbai India

Category : Business

Related searches

Reviews (4)

AHe. I.

Nov 29, 2012

For those who are initializing the lean project is a must have to start doing all the hard work. Congratulations, please keep updating the app.

A. G. u.

Sep 22, 2012

Only tiny part of lean manufacturing covered in free version. Screen shots are only part you get

ROH. B.

Jan 4, 2016

Use full to mech

It is 6th Lean Piller ...