Shaft Alignment

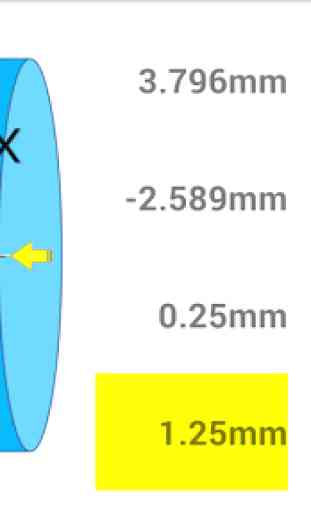

Once the alignment of the axis of the three-dimensional calculations need to move the motor so that you can do to calculate the value.

Calculate the scale of the minimum calculation value to 0.001 mm.

Usage conditions (important)

1. A device that can be fixed to a dial gauge and a motor shaft (e.g. magnet or chain vice versa).

Each one should have one.

Apps can not be used without the above device.

2. The motor is small, so you can't fix the unit

Not available if there is insufficient space to fit the gauge.

You can't afford to buy apps at this point.

How to use

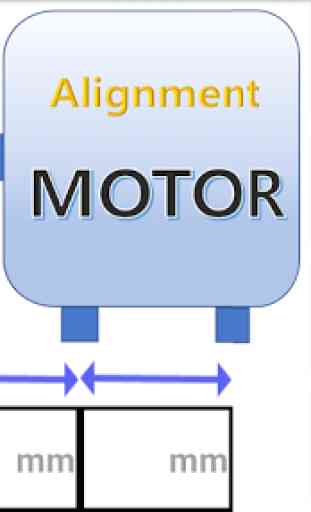

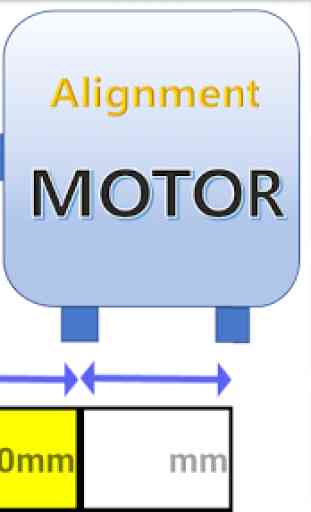

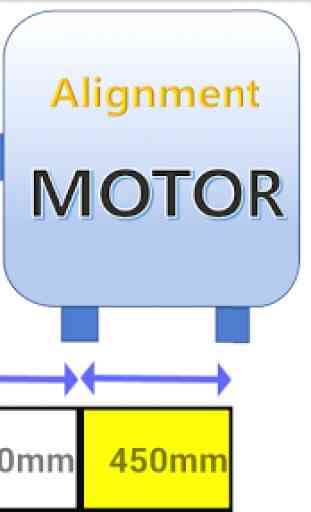

1. Measure the dimensions of the mold.

2. Position the measuring gauge on the motor shaft of the motor and place the dial gauge at the end of the deceleration.

Measure the four gauge values each time the motor shaft is turned clockwise.

3. Place the measuring gauge on the shaft of the moderator shaft at the end of the accumulator shaft at the end of the accumulator shaft.

Measure the four gauge values every 90 degrees by turning the reduction factor clockwise.

4. All units are mm.

Usage use

The axes of the motor axis and the machine are calculated in a straight line.

Calculate the scale of the minimum calculation value to 0.001 mm.

Usage conditions (important)

1. A device that can be fixed to a dial gauge and a motor shaft (e.g. magnet or chain vice versa).

Each one should have one.

Apps can not be used without the above device.

2. The motor is small, so you can't fix the unit

Not available if there is insufficient space to fit the gauge.

You can't afford to buy apps at this point.

How to use

1. Measure the dimensions of the mold.

2. Position the measuring gauge on the motor shaft of the motor and place the dial gauge at the end of the deceleration.

Measure the four gauge values each time the motor shaft is turned clockwise.

3. Place the measuring gauge on the shaft of the moderator shaft at the end of the accumulator shaft at the end of the accumulator shaft.

Measure the four gauge values every 90 degrees by turning the reduction factor clockwise.

4. All units are mm.

Usage use

The axes of the motor axis and the machine are calculated in a straight line.

Category : Productivity

Related searches